A compression spring is a type of open-coil helical spring that offers resistance to a compressive force applied axially. Compression springs can be used for many applications and come in a vast variety of materials, finishes, gages, diameters, and shapes. At Wermke Spring, we are a custom compression spring manufacturer that can custom make any type of custom springs to meet your specifications in quantities as few as one spring up to millions of pieces. All of the compression springs that we manufacture offer high quality and meet the Spring Manufacturers Institute’s (SMI) standards and tolerance requirements. To learn more about our spring manufacturing capabilities, contact the professionals at Wermke Spring.

Custom Made Compression Springs

We have the capability to provide our customers with custom compression springs to meet nearly any specification. If you know the necessary specifications you require, we can manufacture a spring based on your sample or drawing. From basic compression springs to helical compression spring manufacturing, our spring technicians utilize computer software and professional knowledge to create the best spring to optimize performance of any application.

To request a price quote for custom compression spring manufacturing, please complete the form on this page to provide us with the specifications and requirements for your custom spring manufacturing project.

More About Compression Springs

Custom compression springs are available in a wide variety of styles, sizes, materials, and designs in order to meet a diverse range of needs and applications. For example, compression springs can be made in several different shapes, using different types of materials and design fundamentals.

When selecting the type and style of spring that will meet your requirements, it is important to understand and remember that the dimensional tolerances together with the load and deflection requirements will determine the stress level of the spring. Additionally, it is extremely important to carefully consider the space allotted to ensure the proper function of the spring. At Wermke Spring, our spring technicians can consider your requirements and specifications in order to help you select the ideal compression spring design, material, and shape to meet your needs. As leading compression, helical, and valve spring manufactures, we can custom engineer and develop all types of springs for any need.

Several factors that are important to consider when selecting the best type and style of compression spring include:

- Shape: Most compression springs are typically made with a constant diameter. However, some other common shapes of compression springs can include conical, tapered, concave, and convex shaped springs.

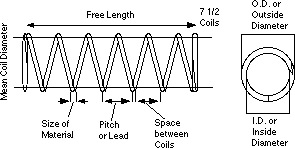

- Material: The most common type of material used for manufacturing compression springs is round wire because it is readily available and adaptable to standard coiler tooling. However, a variety of other types of wire can be used instead in order to meet your specifications including square, rectangular, or any other special section of wire.

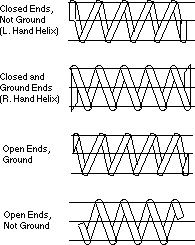

- Design: There are four basic styles of compression spring ends available. These include open ends, closed ends, open & ground ends, and closed & ground ends. Each of these styles has different benefits and advantages.

Learn more about the custom compression spring manufacturing process.

Die Springs: Heavy Duty Compression Springs

Die springs are a special type of heavy duty compression spring that are made using a rectangular wire or heavy gauge round wire. This construction results in a more durable spring that is perfectly suited for high stress applications especially die machinery. Die compression springs can also be used in a variety of additional applications as well.

At Wermke Spring, we can manufacture die springs in a variety of sizes in order to meet any specifications and requirements.

Learn More About Our Compression Spring Manufacturing in the Midwest

As a leading St. Louis spring manufacturer serving clients nationwide, we look forward to partnering with you for all of your spring engineering and design needs. To learn more about our compression spring manufacturing capabilities or to request a quote for your custom order, please contact the spring professionals and experts at Wermke Spring today.