Extension springs are a type of spring that are designed to store energy and offer resistance to a pulling force. These springs typically have hooks, loops, or end coils that can be attached to separate points and then used to pull the spring apart. Custom extension springs can be used in a wide variety of applications and are available in many different sizes.

At Wermke Spring, we manufacture a variety of types of extension springs in many sizes and dimensions. These springs are all designed to offer high quality and will meet the specifications of the Spring Manufacturer’s Institute (SMI). To learn more about our extension spring manufacturing services, please contact the experts at Wermke Spring today.

Our Custom Extension Spring Manufacturing

If you require custom extension spring manufacturing in order to meet your specific requirements, our engineers can help. We will work with you using computer software software and professional knowledge in order to help engineer the best extension spring to optimize performance of any application. We can even provide a prototype to ensure that performance expectations are met.

Whether you need only one or a few springs or you require millions of springs in a custom style, we can supply the springs to meet your needs. For a price quote for your extension springs or to work with our engineers to develop the extension springs that meet your requirements, please contact us or complete the form on this page.

More About Buying Extension Springs

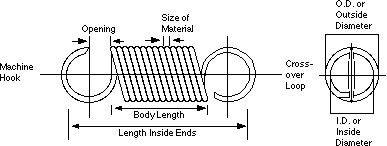

Extension springs are helically wound and made from tightly wrapped coils that create a tension. These springs have some type of hook or loop at each of the ends, which are typically attached to different components. Then when these components move apart, the extension spring absorbs and stores energy and provides a tension or pulling force to pull these components back together. The initial tension of the spring determines how tightly the spring is coiled. This tension can be manipulated during manufacturing to achieve the load requirements of a particular application.

Extension Spring Configurations

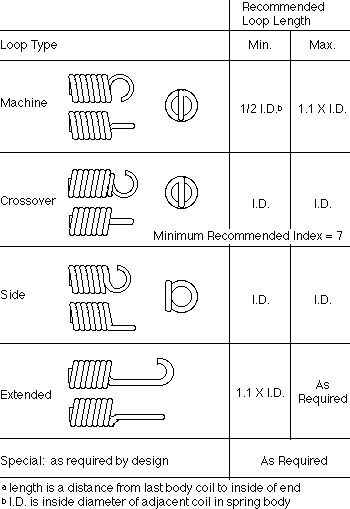

There are a variety of ends that can be used when configuring and engineering extension springs. The most common configurations used for extension springs are full loops and crossover hooks, because these can be made with standard tooling and minimal cost. Other options for extension spring end configurations may include:

- Threaded Inserts and Plugs

- Reduced or Expanded and Extended Hooks or Loops on the Side or Center of the Spring

- Hooks at Varying Positions or Distances from the Spring Body

- Different Shapes such as Rectangular or Teardrop-Shaped Loops

When engineering extension springs, it is important to remember that most extension spring failures occur where the hook meets the body of the spring. Therefore, to maximize the life of the spring, the path of the wire should be smooth and gradual as it flows into the end. Additionally, stress in the hook/loop area should be held to a minimum, with a bend radius not less than 1.5 times the wire diameter. For additional hook configurations, please contact us.

Extension Spring Applications

Extension springs can be made to fit nearly any specifications and can be used for a wide variety of applications. This includes for:

- Industrial Equipment and Machinery

- Manufacturing Processes

- Automotive Interior and Exterior Components

- Farm And Off Road Machinery

- Garage Door Assemblies

- Hand/Power Tools

- Sporting/Athletic Equipment

- Appliances

- Toys

Order Custom Extension Springs in St. Louis & Nationwide

If you would like to learn more about our ability to manufacture custom extension springs for your intended application, please contact us. Based out of St. Louis, Missouri, we partner with clients throughout the Midwest and nationwide. You can complete our form online to provide us with your specifications and requirements in order to receive a quote for your specific spring needs.