Torsion springs are helical shaped springs that exert a torque in a rotary force. The tails of these springs are typically anchored to other components. When those components are rotated around the center of the spring, the spring applies a force to push them back to the original position. These springs can be engineered for use in a clockwise or counterclockwise rotation depending on the direction of the wind. Additionally, they can be made in many different sizes and configurations in order to meet nearly any specifications.

At Wermke Spring, we can manufacture torsion springs in a variety of different styles and sizes. All of the springs we manufacture are engineered to provide high quality in order to meet your requirements. To learn more about our custom torsion spring manufacturing process and capabilities, please contact the professionals at Wermke Spring.

Our Custom Torsion Spring Engineering & Manufacturing

If you need custom spring manufacturing for any application, our experts can utilize the latest computer software to develop torsion springs to meet any specifications. We will work with you to understand your needs and develop custom solutions that can optimize system performance, life, and integrity. Whether you need only one spring or millions, we can meet your needs.

To request a quote from our custom torsion spring manufacturer, submit our quote request form to provide us with the specifications and requirements for your order. You can also call us directly at (636) 677-5500 to discuss your needs with our professionals.

More About Torsion Springs

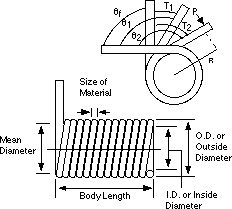

Torsion springs are springs that are designed with ends that can be rotated in angular deflection. This offers resistance to externally applied torque. Most torsion springs are usually close wound to maximize tension, but some can have a pitch or space between the coils to reduce friction. These springs reduce in coil diameter and increase in body length as they are deflected. This is important to remember during spring engineering and planning as you will have to account for the extra space needed for this increased length. The effects of friction and arm deflection on the torque must also be considered in the engineering process.

Torsion Spring Configurations

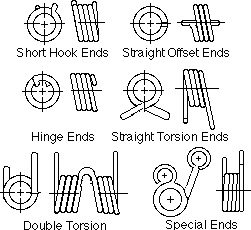

There are a variety of options available for tail or end configurations of torsion springs and these can be customized to meet your specifications and to allow the spring to be anchored in several different ways. For example, the legs may be located at varying positions, angles, or distances from the body of the spring. Additionally, torsion springs can have legs that are shaped in many different styles and lengths. These can be bent, hooked, or looped to suit your needs.

One popular special type of torsion spring is a double torsion spring. Double torsion springs consist of one right-hand and one left-hand coil section that are connected together. These work in parallel with the total torque exerted being the sum of the two.

Some possible torsion spring configurations include:

- Short Hook Ends

- Straight Offset Ends

- Hinge Ends

- Straight Torsion Ends

- Double Torsion

- Special Ends

Torsion Spring Applications

Custom torsion springs can be used in all types of applications including during manufacturing processes, as part of industrial equipment and machinery, and as part of finished products. Some common applications for torsion springs include for:

- Trailer Ramps

- Clothes pins

- Clipboards

- Swing-down tailgates

- Garage doors

- Electronic devices

- Chair control units

Order Custom Torsion Springs in St. Louis and the Midwest

As a leading spring manufacturing and engineering company based out of St. Louis, MO, Wermke Spring serves clients throughout the Midwest and nationwide. To learn more about torsion springs or to place an order for the custom torsion springs to meet your needs, contact our spring manufacturer or submit your specifications using our online quote request form.