Are you wondering what the custom compression spring manufacturing process includes? Do you want to know the necessary steps of this process and how we create custom compression springs to meet your needs? If yes, then read on to learn more.

As a leading custom compression spring manufacturing expert in St. Louis, Wermke Spring has been in this industry for 70 years. We not only work with clients in the Missouri region but also from the Midwest and other parts of the country. So, no matter where you are or what your custom compression spring requirements are, we have the capability to handle them. Contact us to learn more or request a quote for your spring manufacturing needs.

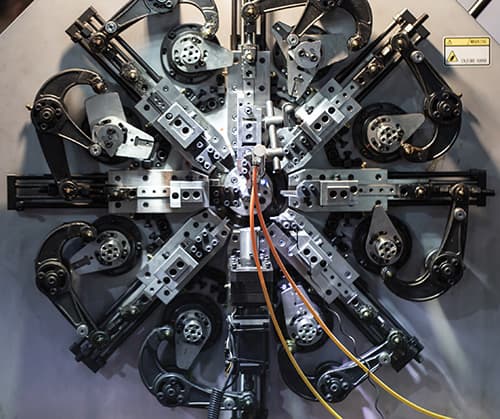

Our Compression Spring Manufacturing Process

When you work with Wermke Spring, our typical compression spring manufacturing process follows some key steps. These include:

1. Choosing the Right Custom Compression Spring Manufacturing Spring Partner

Choosing the right partner for your custom spring manufacturing needs is essential, and this is the first step in any project. Hiring an experienced and skilled manufacturer ensures you will get top-notch results. At Wermke Spring, our seasoned team does not just perform the manufacturing process; we partner closely with you throughout the engineering journey.

From custom spring clips to custom compression springs, we will collaborate with you to ensure the spring design aligns precisely with your project’s unique specifications. We will follow your instructions and provide insights and guidance whenever necessary.

2. Understanding Your Design Requirements

Every custom compression spring manufacturing process starts with understanding the customer’s spring design requirements. At Wermke Spring, our team works closely with you or your team to understand the important specifications and requirements of the design you want.

We focus on everything from the size of the compression spring to its shape, dimensions, and specific load-bearing capabilities. Our goal is to understand your needs and come up with a design that meets them perfectly.

3. Material Selection

Choosing the right material is an integral part of our custom compression spring manufacturing process. While choosing the material for your custom compression springs, focus on several critical factors, including corrosion resistance, tensile strength, and resilience in different temperatures and environmental conditions. We are committed to excellence and source the highest quality materials from a variety of vendors around the country. Thus, you can rely on the longevity and reliability of the materials employed in your custom compression springs.

4. On-Time Delivery

Delivering your compression springs on time is an important part of our process. Our spring manufacturing process is optimized to deliver products punctually. This ensures that there are no delays and unnecessary losses for your business.

Contact Wermke Spring for the Best Custom Compression Spring Manufacturing Services

Now that you know about the compression spring manufacturing process, are you looking for professional assistance? If yes, we at Wermke Spring can help you out. Get in touch with us to discuss your custom compression spring manufacturing needs. Fill out the contact form on our website or call us directly at (636) 677-5500 to discuss your needs.